More runs instead of empty runs

With the Combiliner tipping semi-trailer - Version 3.0 - we present a very flexible transport system. We have further optimised the transport solution for alternating transports of liquid and solid goods without conversion in many areas for version 3.0. A aluminium semi-trailer is extended by a modular construction with a flexible transport bag to make alternating transports of liquids and solids possible without conversion.

Innovative character

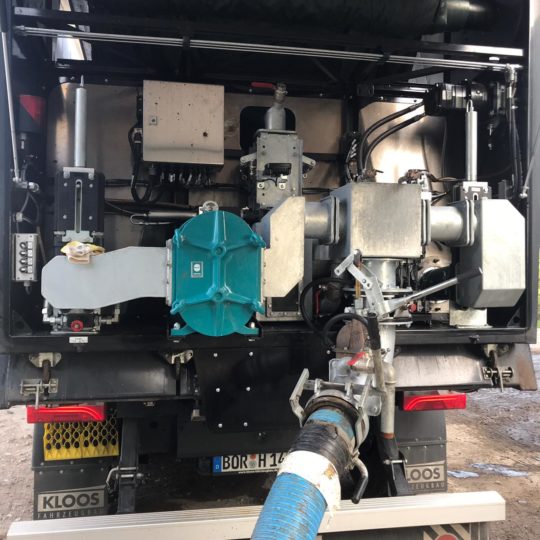

In its normal state, the aluminium body has a loading volume of either approx. 47.5 m³ or 53 m³ for solid bulk goods. With the system flap - pump technology and flexible transport bag instead of the normal tailgate - the combined transport of solid and liquid goods is made possible. By using a high-strength PVC/TPU membrane with very good chemical resistance, the transport bag can be filled not only with liquid manure, but also with water, liquid feed, liquid fertiliser and other liquids. Thanks to the compact installation of the system solution in the volume flap, it is possible to use the full loading volume of the dump trailer for solids. Due to the fast and efficient removal of the system flap, duration approx. one hour, the payload is increased by approx. 1,400 kg when driving with the standard flap. The bulk volume of the skip is thus increased by approx. 2 m³. Due to the short overall length, the trailer is compact and manoeuvrable. Optionally, the already high manoeuvrability can be further increased by a self-steering axle or OptiTurn.

Transport of feed

Our Combiliners have been inspected by GMP and QS. The Combiliners can be certified within the scope of an audit by both companies. Please refer to the respective specifications of the companies. For the transport of liquid feed we offer a corresponding supply line technology made of stainless steel and a modified rotary lobe pump.

Two-tank venting and flushing function

The use of a two-tank venting system makes it possible to preload. The open venting system ensures that the gas that forms can escape. The system also vents while driving. Due to the flange connections on the left and right of the flexible transport container, we can enable a flushing function in both directions with the help of the rotary lobe pump. Especially during longer transport times, the thick and thin phases of the liquid separate. The flushing function before emptying restores a homogeneous liquid that can be emptied evenly. To prevent the membrane from being sucked into the supply lines during the emptying process, we protect this area with wire baskets. We have installed flushing baffles in the wire baskets to achieve a flushing function in all directions.

Flexible transport bag

Our flexible transport bag has an engineer-calculated design that supports venting. The slightly rising shape forces the gas to collect at the highest point, gas collection bubble, where it is discharged through a 4 inch overflow hose into the two-tank system.

Furthermore, during the winding process we use a pull tab that is welded completely underneath the transport tank. This pull tab absorbs the forces that arise when emptying the container, as we empty and wind the container at the same time. In this way, we achieve optimal emptying without residues. The pull tab protects the bottom of the flexible transport container as a second layer. The flexible transport container itself therefore does not come into contact with the floor of the trailer.

Progress through digitalisation

Digital control options (optional) in the form of a touch panel enable the user to visualise and monitor active processes. In addition, a network camera installed in the interior of the trailer body can be switched to the touch panel display and thus used as a monitor. A network connection for remote maintenance completes the digital equipment options.

Further advantages of the system

The combiliner transport solution can take over the tasks of two different vehicles - a great economic and ecological advantage. The volume flap does not impair the tipping function of the body. The flap can also be opened more than 90° for unloading bulk goods. This function enables the transport of pallets, straw or other general cargo. For seasonal transports, for example sugar beet, the volume flap can be exchanged for the standard swing flap (option) to enable a higher payload.

Features

- Avoidance of empty runs due to alternating traffic

- Economic and ecological efficiency

- Tested and certified by TÜV Süd

- Suitable for transporting feedstuffs in accordance with GMP and QS requirements

- Flexible transport bag can be extended by pump technology and rolled up hydraulically - EU patent

- Control by remote control, possibility of remote maintenance

- Flushing function

- Filling/emptying possible with external pump

- Pre-charging possible by two-tank venting

- Swivel connection

- Weight-optimised rotary lobe pump, output up to 6,000 litres per minute

- Optional inclusion of suction and pressure hoses in 6 inches

- Optional standard rear flap made of aluminium with slide valve and dust bag

- Optional storage rack for both flap variants

Features of flexible transport bag

- PVC/TPU coated fabric with increased UV resistance

- Kink resistant; no cracking after 100,000 kinks

- Temperature resistance from - 30° C to + 70° C

- Chemical resistance against slurry/acid/ammonium nitrate, among others

- 3 years warranty